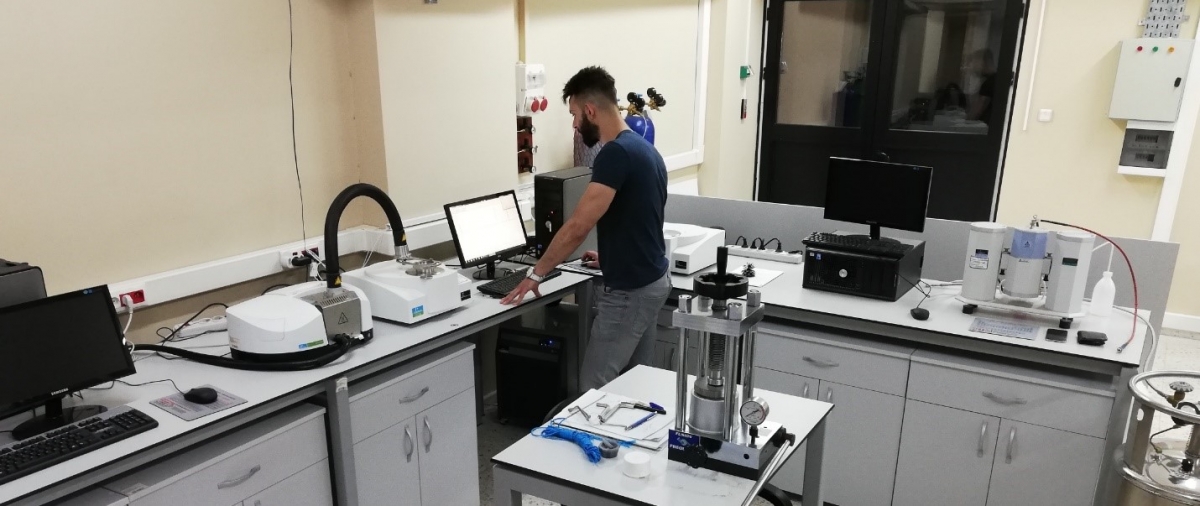

The “Composite Materials Characterization Laboratory” focuses on the characterization of the composite materials used in the Aerospace and Wind Energy industries and on design, analysis, and optimization of structures composed of composite materials using experimental and numerical techniques.

There are three main focus areas of the lab:

• Composite material characterization

• Composite material manufacturing

• Design, analysis, and optimization of structures composed of composite materials

|

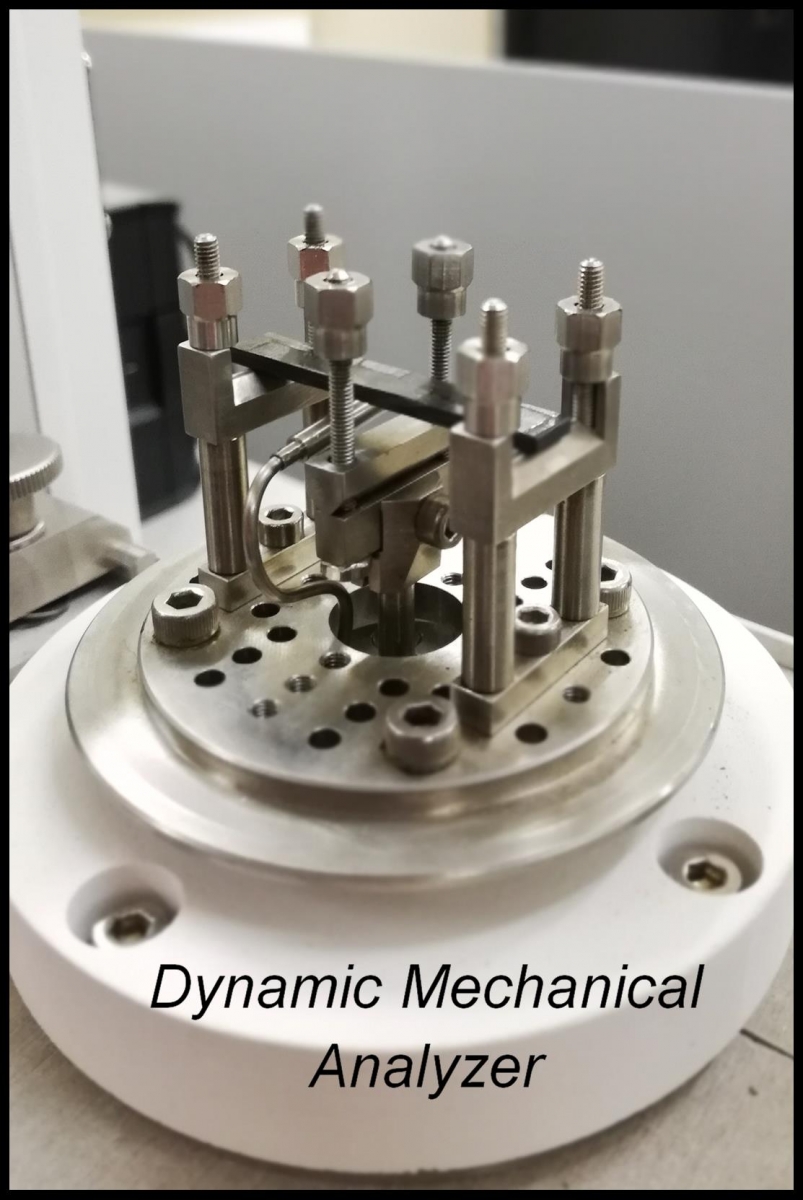

The first focus area is the characterization of thermal and mechanical behaviours of composite materials, including base resin systems and fiber reinforced composites The second focus area is the composite manufacturing of fiber reinforced composite which involves issues like toughening mechanisms used for resin systems, techniques to improve damage tolerance of composite materials, resin flow simulation of processes such as resin transfer moulding, vacuum infusion, permeability test and simulation of different fabric forms and resins systems and the effect of the manufacturing method on mechanical characteristics of fiber reinforced composites. The third focus area is the design, analysis, and optimization of structures composed of composite materials using experimental and numerical techniques. Testing EquipmentMeasuring equipment in the “Composite Materials Characterization Laboratory: - Perkin Elmer – Lambda 35 UV/Vis Spectrophotometer - Perkin Elmer – DSC 4000 Differential Scanning Calorimeter - Perkin Elmer – TGA 4000 Thermogravimetric Analyzer - Perkin Elmer– Spectrum Two Spectrometer - Perkin Elmer – DMA 8000 Dynamic Mechanical Analyzer |

|

Testing equipment in the “Structural Mechanics and Materials Testing Laboratory:

- Dartec 100 kN Servo-hydraulic Axial Testing Machine

- MTS 250 kN Servo-hydraulic Axial Fatigue Testing Machine

- MTS 100 kN – 1100 N×m Servo-hydraulic Axial/Torsional Fatigue Testing Machine

- MTS 100 kN Electromechanical Testing Machine with MTS -100 – +350 °C Environmental Chamber

Visualization and measuring equipment in the laboratories:

- 3-D Digital Image Correlation System

- Strain Gage Instrumentation

Click here for technical specifications of the devices and detailed testing capabilities.

Click here for technical specifications of the devices and detailed testing capabilities.

İletişim

|

Prof. Dr. Altan Kayran Professor in the Department of Aerospace Engineering, METU, Coordinator of METUWIND Composite Materials Characterization Laboratory Phone: (+90-312) 210 4274 e-mail: akayran @metu.edu.tr Web: http://www.ae.metu.edu.tr/~kayran/ |