| ÖLÇÜM EKİPMANLARI |

|

Model Wind Turbine Test Rig

Specifications:

- 1 m to 1.4 m diameter rotors (adjustable pitch angles)

- Ability of air injection from hub to the channels in blade roots to investigate active flow control for various applications

- Driven by 1.5 KW Panasonic Servo Motor

- Equipped with HBM T20WN/5 Nm torque transducer

- Equipped with a 6-axis ATI Force/Torque transducer

Applications:

- Performance measurements studies

- Flow field measurements studies

- Active flow control studies

- Passive flow control studies

|

|

|

|

High Precision Force/Moment Balance

Specifications:

- Load balance system equipped with 6-axis ATI Force/Torque transducers

- Equipped with a stepper angle motor for angle of attack adjustment

Applications:

- Aerodynamic characteristics measurements of wing and bridge models in wind tunnels

|

|

|

|

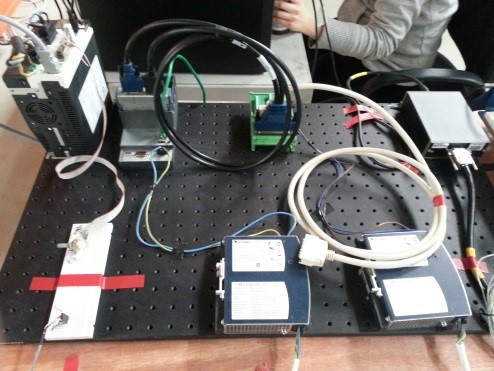

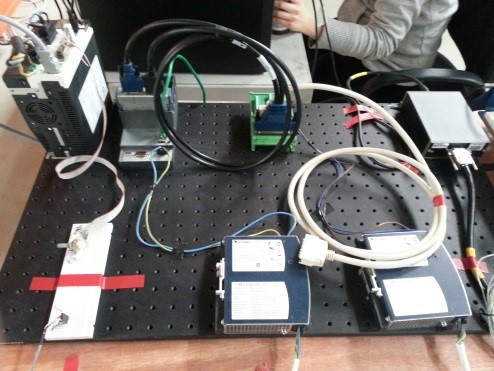

Particle Image Velocimetry

Specifications:

- TSI Incorporated

- Two Dimensional, Stereoscopic, Time-Resolved, Particle Image Velocimetry System

- Litron LDY304 series diode pumped Q-switched Nd: YLF high repetition rate (0.2-20 kHz) laser. The laser is a dual power, dual cavity with output energy at 1 kHz at 527 nm up to 30 mJ per laser head per pulse

- Two 12-bit high speed (Phantom V640) digital camera with a maximum resolution of 2560x1600 pixels at a frequency of 1.5 kHz (4 megapixel at full resolution) and 16 GB of internal memory buffer

- A Model 610036 LASER PULSE Synchronizer

- A 3-Axis ISEL heavy duty traverse system utilized for capturing image data at multiple planes in a flow.

- A six-jet oil droplet generator that utilizes a Laskin nozzle to generate droplets of 1 µm in diameter, used for flow seeding. Pressurized air atomizes oil in the generator reservoir to produce the droplets. These generators are best used with olive oil.

- INSIGHT 4G Acquisition Data System Software

- LASER PULSE Light Arm

- Various Light Sheet Optics. Various camera lenses and filters

- Breadboard, Laser safety Glasses

|

|

|

|

Pressure Measurement

Specifications:

- 128-channel ESP pressure scanner units

- DTC Initium DAQ pressure measurement system

- 16-channel DSA pressure Scanner from Scanivalve Corp

Applications:

- 5-hole pressure probe

- Pitot-static pressure probes

- Kiel probe

- Surface pressure measurements on wings

|

|

|

|

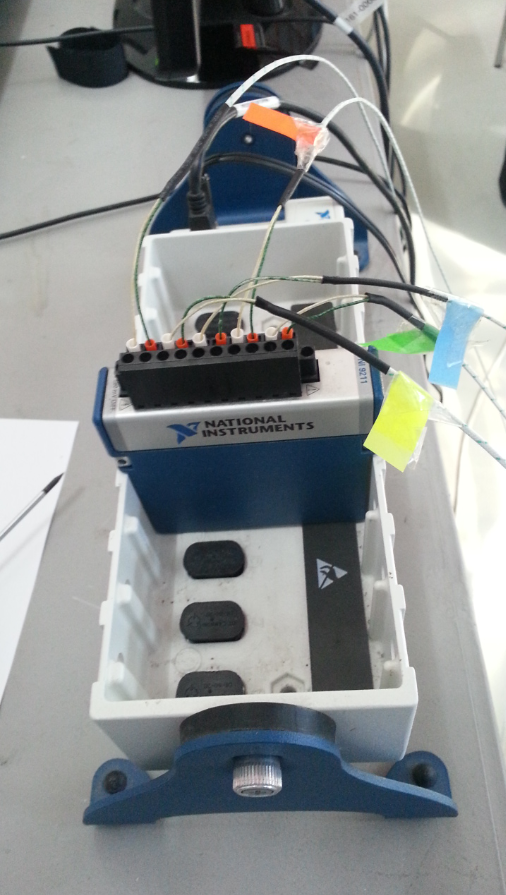

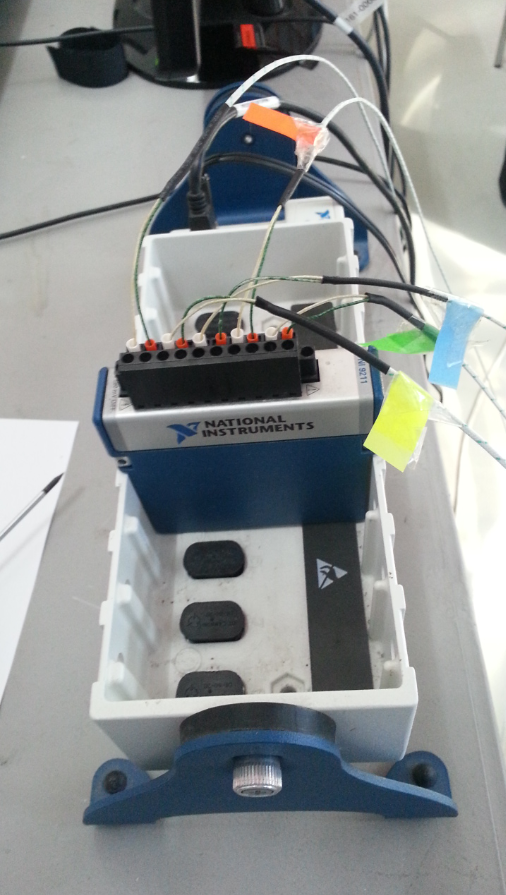

Data Acquisition System

Specifications:

- NI Compact DAQ -9172 8 slot USB Chassis

- 2 x 32-channel NI-9205 analog input module

- 8-channel NI-9472 24 V Sourcing Digital Output

- 4-channel NI-9211 Thermocouple analog input module

- NI Compact RIO-9076 4 slot Ethernet Chassis

- NI-9512 1 Axis Stepper Drive Interface Module

- LABVIEW programing software

Applications:

- Constant Temperature Anemometry (CTA) Measurements

- Pressure Measurements

- Motion Control Measurements

|

|

|